Features

- Ribbon Types

Standard ribbons are used for general mixing, intermittent ribbons are suitable for viscous materials; for very abrasive mixing tasks, the ribbons can be designed with bolted replaceable connections for easy replacement when worn.

- Continuous Operation

Mixers for continuous operation are provided when large volumes of the same material need to be processed per hour. Continuous ribbon mixers differ from intermittent mixers in that the mass flow of the product is from the inlet of the container to the outlet at the other end.

- Heating/Cooling Jackets

Jacketed troughs for steam, thermal oil or water heating/cooling operations.

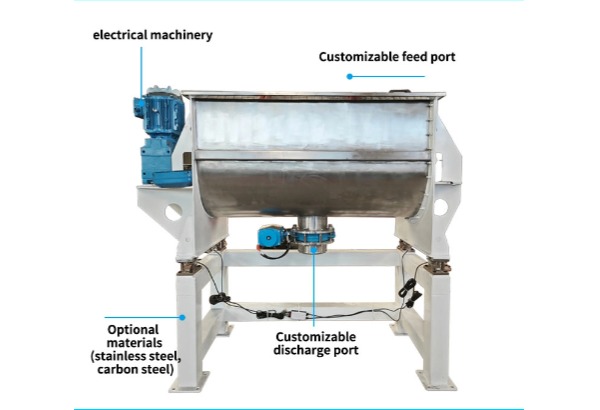

- Customized Inlet and Outlet

A variety of inlet and outlet options are available. The feed can be designed with a sliding cover for applications with limited height; the bag unloading station can be installed on the top of the U-shaped trough. Safety barriers can be installed to prevent possible injuries to workers. For the discharge of the product, manually, pneumatically or electrically operated valves can be selected according to the customer's preference. They can be easily integrated into any existing production line.

.jpg)